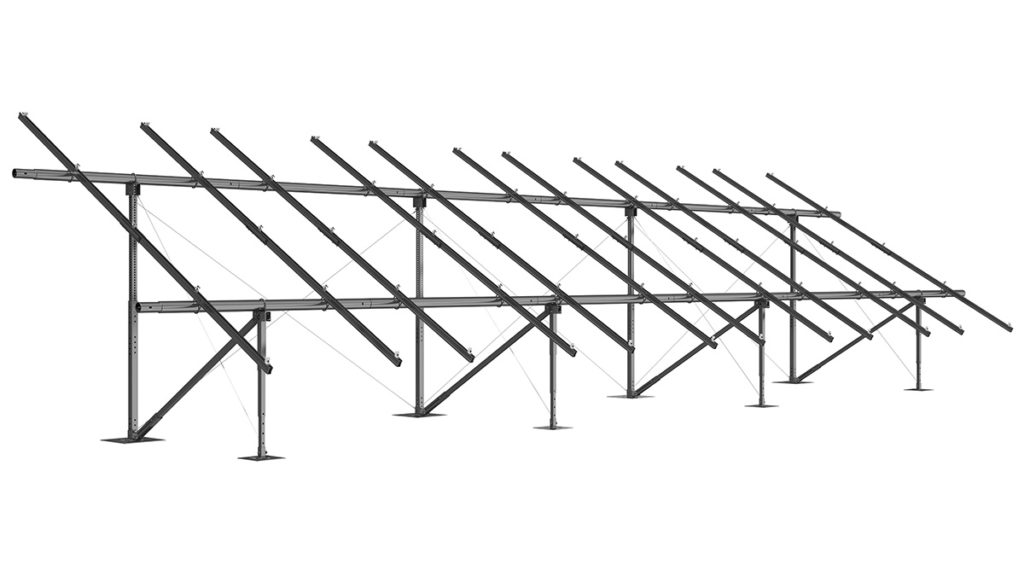

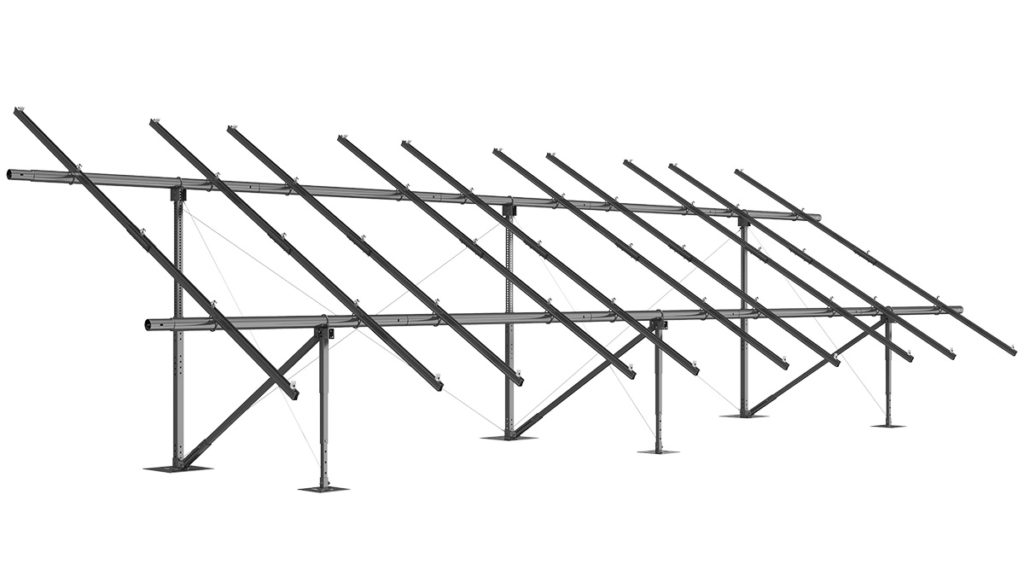

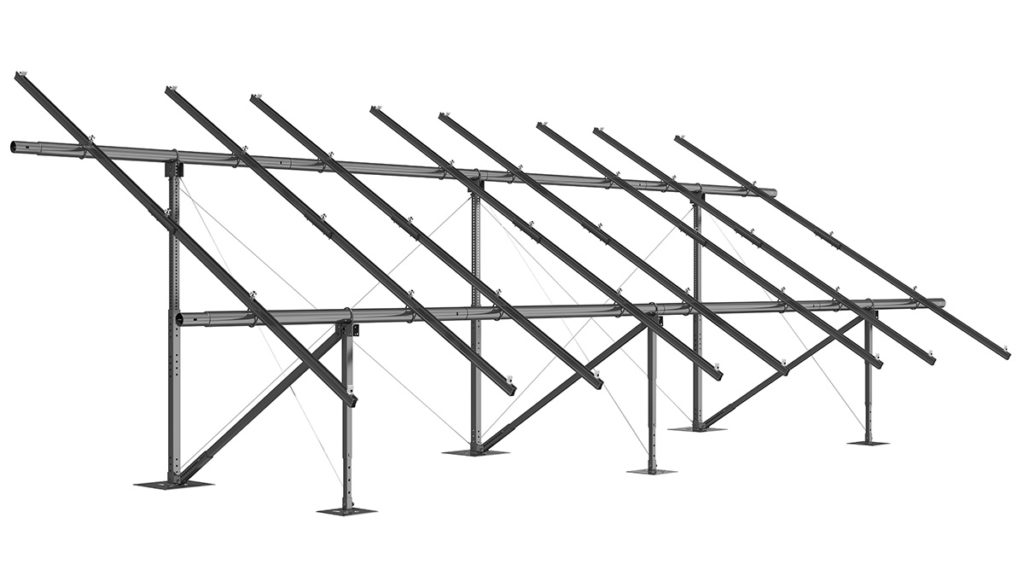

OPR 4×6-4

OPR LTE™

-

- Landscape configuration

- Designed to hold smaller solar panels (60 cell and 72 cell) up to 450w

- Wind < 140mph and snow load < 60psf

- Tilt angle (15° – 35°); custom to 45°

- Available Table Sizes and # of Foundations:

-

- 4×3-2 4×5-3

-

- 4×3-3 4×5-4

-

- 4×4-2 4×6-4

-

- 4×4-3

-

- Custom arrangements up to 4×12 are also available

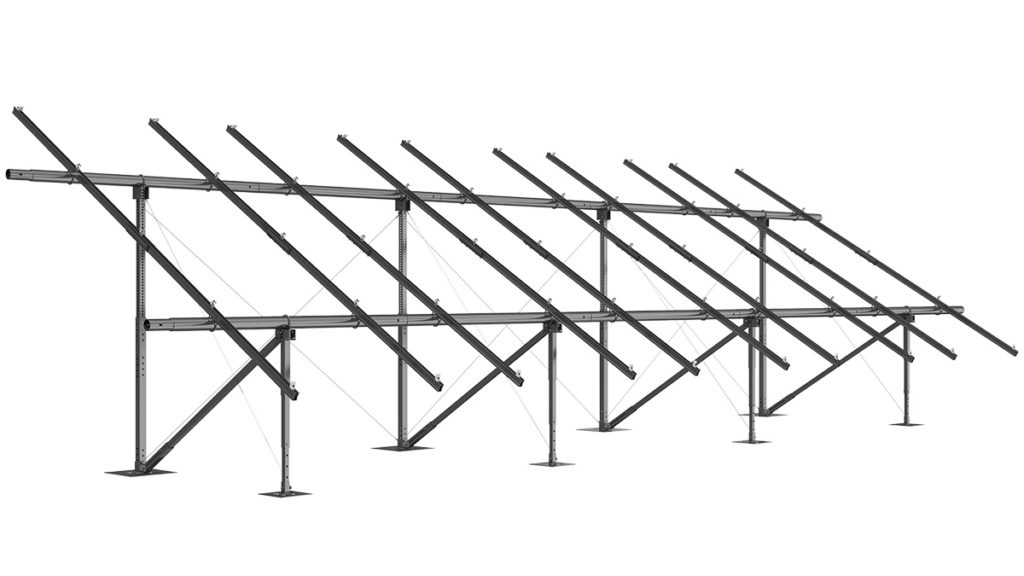

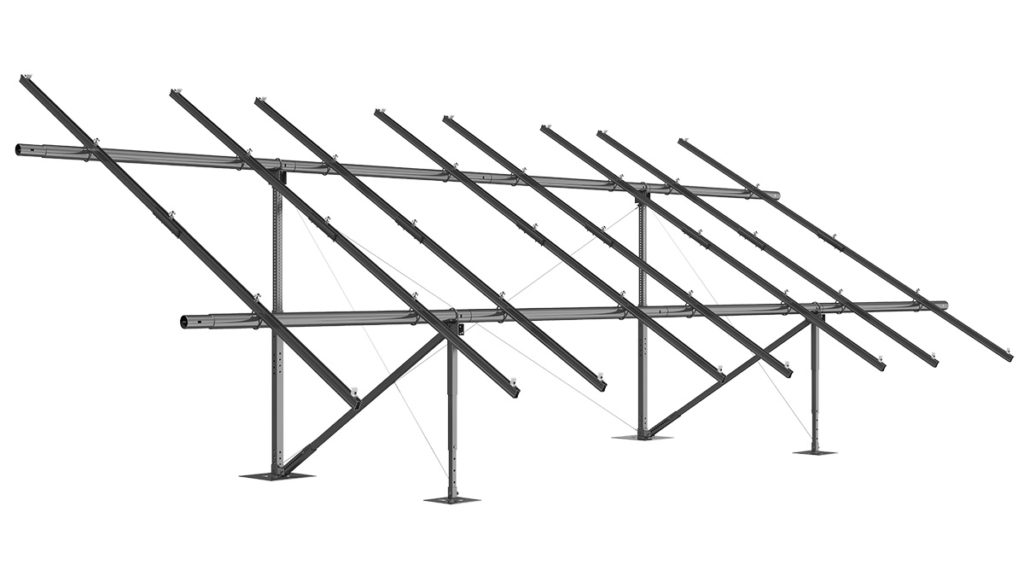

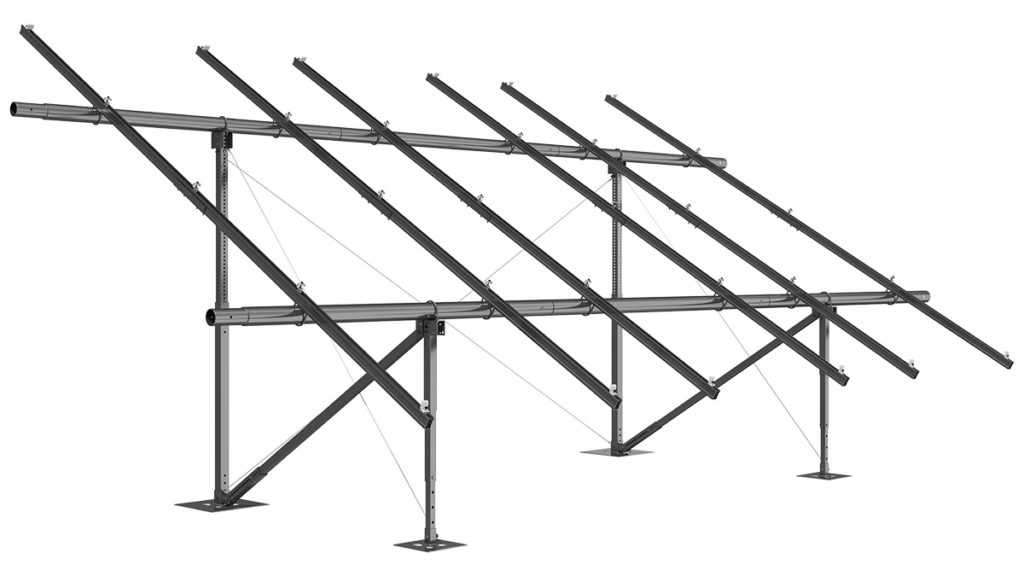

OPR MAX™

-

- Landscape configuration

- Designed to hold larger solar panels from (450w – 585w)

- Maximum dimensions (45” wide x 90” or longer)

- Wind <110mph and snow load < 30psf

- Tilt angle (15° – 35°)

- Available Table Sizes and # of Foundations:

-

- 4×3-2 4×5-3

-

- 4×3-3 4×5-4

-

- 4×4-2 4×6-4

-

- 4×4-3

-

- Custom arrangements up to 4×12 are also available

FASTEST COMMERCIAL SOLAR INSTALLATION TIME + DRAMATIC COST REDUCTIONS

CONVENTIONAL FOUNDATION INSTALLATION

2MW INSTALLATION

DAYS TO INSTALL

*Conventional installation of foundations and survey only

VS

OSPREY PowerRACK®

2MW INSTALLATION

DAYS TO INSTALL

*Fully trained, 16-person crew installing the foundation, racking and modules

SAVINGS

*Savings due to lower field labor costs, no pile driving, and no geotechnical reports

OSPREY PowerRACK® VALUE PROPS

Nuance Energy’s OSPREY PowerRACK® is a multi-patented ground mount solar racking system designed to save time and money in the solar industry.

The OSPREY PowerRACK® differentiates itself from conventional ground mount solar racking solutions with its modular design and “kitted” components. This design addresses various installation challenges for installers and distributors, including those listed below.

1. LOWEST COST OF LABOR IN SOLAR

The OSPREY PowerRACK® eliminates the need for higher-wage field installers. A 3-4 person crew with 30 minutes of training can typically assemble 10kW+ tables in about an hour, including the racking, foundations, panels, and anchor load testing. Installers can increase their installation speed to up to (50kW – 70kW) in an 8-hour shift with adequate practice.

2. NO COSTLY EXCAVATIONS

The OSPREY PowerRACK® features Nuance Energy’s multi-patented earth anchor foundation technology, eliminating the need for conventional foundation methods like pile-driven foundations, helical screws, concrete piers, or ballast blocks. This requires minimal site preparation or grading, reducing installation time and overall costs.

Unlike other racking systems that use helical screws or post-pounded steel foundations, which may experience refusal rates due to hard or rocky soil, the earth anchor foundation system has no refusal rate. This avoids delays and extra costs.

The OSPREY PowerRACK® is suitable for challenging terrains or areas with hard soil or rock, offering cost-effective, efficient, and low-impact installation.

Customers benefit from the minimal disturbance caused by the OSPREY PowerRACK’s earth anchor foundation system. However, erosion control measures may be necessary for N/S or E/W slopes greater than 10°, potentially adding additional cost to install.

3. NO EXPENSIVE ON SITE MACHINERY

The OSPREY PowerRACK® does not require heavy machinery for installation, avoiding large upfront investments in expensive equipment. Only handheld tools are required, and no on-site welding is necessary.

Solar installers can invest in the required tools for less than $3,000. Solar distributors can rent or sell these same tools.

4. NO GEOTECHNICAL REPORTS

A key patent claim of the OSPREY PowerRACK® is its real-time soil condition anchor “load testing,” eliminating the need for geotechnical reports on commercial projects. This feature differentiates it from other conventional solar ground mount systems.

The OSPREY PowerRACK® can save approximately $145,000 on a standard 2MW solar installation translating to about $0.07 per watt.

A 2MW commercial solar installation, which normally takes over 60 days to become fully operational, can have its foundations, racking, and solar modules installed in just about 16 days with the OSPREY PowerRACK®.

These savings, along with the quick installation time, make the OSPREY PowerRACK® an efficient solution for installers, contractors, developers, or EPCs.