The Osprey PowerRACK®

Engineered for speed and adaptability, the Osprey PowerRACK® uses our multi-patented earth anchor foundation technology to tackle the toughest terrain and deliver residential solar installers’ ground mount solar projects in record time without the need for geotechnical reports, concrete, or heavy machinery.

With mobilization, installation, and real-time pull testing in one day, the Osprey PowerRACK® lets you stay in control of your install schedule, avoiding costly delays and reducing project risk with predictable labor costs.

The Osprey PowerRACK® is more affordable than traditional racking solutions with much lower labor costs, minimal upfront investment for tools, and turnkey engineering services.

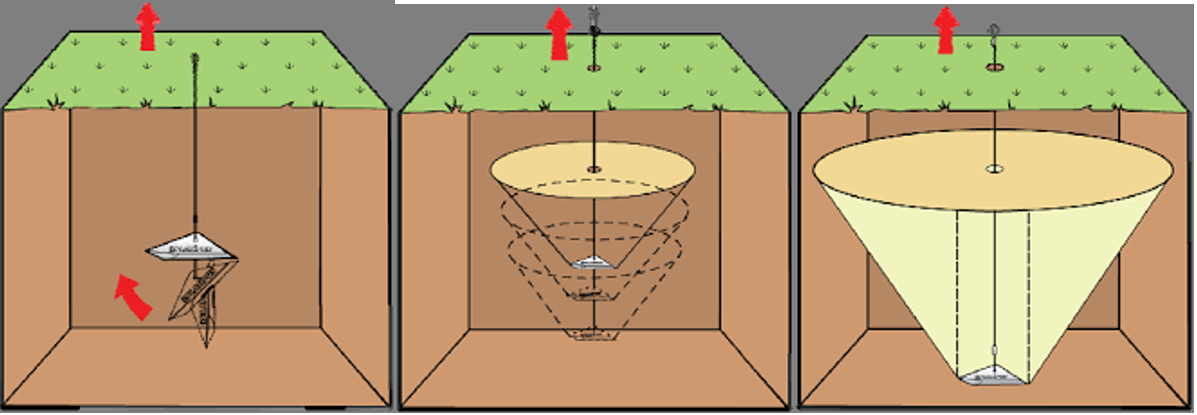

What is an Earth Anchor?

Earth anchors are not ground screws nor helical piles, so there is no need for heavy equipment. They have been used for over 100 years to stabilize structures like retaining walls and high-tension power lines. Earth anchors are extremely strong, versatile, and fully capable of handling harsh conditions like frost heave, permafrost, desert hardpan, red clay, and even winds up to 185 mph.

Unlike helical piles and ground screws, earth anchors do not require concrete and can be installed with basic handheld tools. There is zero disruption to the residential job site. Compact and nimble, they are about the size of a cell phone and provide a much faster, more economical installation than traditional solar foundation types, while maintaining the same level of holding capacity.

Nuance Energy is a trailblazer in the solar industry and the only OEM offering earth anchor foundation technology with real-time soil condition pull “load” testing, making solar installations faster, more affordable, and accessible to all.

Check out our article in Solar Power World to learn more.