Accelerate Your Commercial Solar Projects with the Osprey PowerRACK®

Complete installs in hours, not days, with the Osprey PowerRACK®. This pre-engineered, modular racking system is built for speed and adaptability, featuring advanced earth anchor foundation technology and turnkey engineering services for rapid and streamlined deployment to scale across large solar sites.

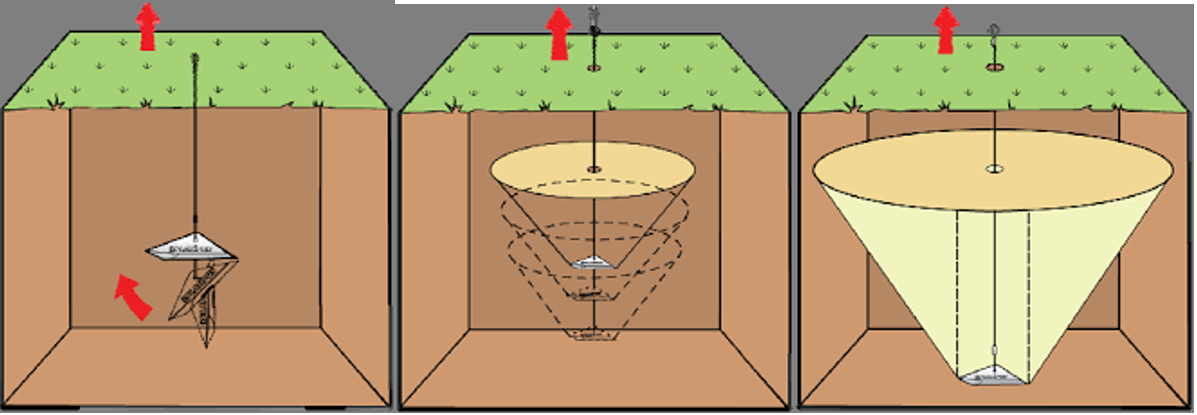

The Osprey PowerRACK® simplifies every step of solar ground mount installs without any specialized labor, heavy machinery, geotechnical reports, or concrete. Control your installation schedule, minimize project risk, and boost profitability with 4x faster installs than traditional ground mount systems.

The Osprey PowerRACK®’s versatile design allows commercial solar installers to build on any challenging terrain and soil conditions with minimal environmental impact. With same-day mobilization and installation, you can achieve fast and efficient installs that significantly cut labor costs and keep projects on schedule.

![]() Pre-engineered for fast, one-day mobilization and install

Pre-engineered for fast, one-day mobilization and install

![]() Save significantly on labor costs with faster, simpler installs

Save significantly on labor costs with faster, simpler installs

![]() Control your install schedule with no geotechnical reports, concrete, or heavy machinery

Control your install schedule with no geotechnical reports, concrete, or heavy machinery

![]() All-terrain adaptability to build anywhere

All-terrain adaptability to build anywhere

![]() Minimal site disruption to save on grading with low environmental impact

Minimal site disruption to save on grading with low environmental impact

![]() Pre-kitted for modularity and efficiency across large sites

Pre-kitted for modularity and efficiency across large sites

![]() More predictable cost of project install, with most expenses in materials

More predictable cost of project install, with most expenses in materials

![]() Overcome refusal rates with easy installation at any angle

Overcome refusal rates with easy installation at any angle

![]() Reduce change orders with an adaptable universal rail system

Reduce change orders with an adaptable universal rail system